You input the rough openings, overlap stile and desired width of the rails and stiles and from there it calculates a cutting list.Ĭhoose the download link below and we’ll email it to you AND a few special tips from the School of Woodwork! You can use a simple Excel spreadsheet to calculate all the dimensions. When overlapping, 1/4″ will need to be added to the face frame’s rough opening dimensions on all sides to arrive at the overall door size. For double doors, the 1/4″ add-on to the rough opening is applied to both doors taken as a whole. Many kitchen cabinets use full-overlap but when making a furniture piece the style can vary widely. The rough opening of the door opening needs to be measured.

This decision is as much as aesthetic one and will determined by the aspects of the piece of furniture you are building.ĭoors are generally built after the carcass is assembled. Next, you must decide if your door will be mounted either: flush, full-overlap, or half-overlap to the cabinet face. The photo below is of a cutter set from, they offer a nice range of different styles.Ĭutter Set from What size should you cut your door parts?

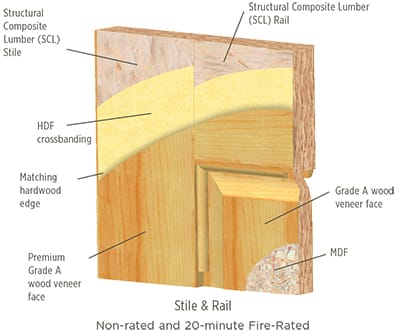

This bit is used on both the doors and drawer fronts of a cabinet. Some door cutter sets also come with an outside edge profile bit.This allows them to make the bit smaller and lighter. Due to the limitations of some routers, router bit manufacturers have produced raised panel cutters that require the panel be vertical when pushed past the cutter. Keep all the safety guards on your machine. Mine is 5” in diameter! It can be a bit intimidating when spinning at 12,000 RPM (shaper) or 20,000+ RPM (router). This can be a very large cutter due to the size of most raised panel profiles. This cutter is used on the ends of the rails to cut the mating profile. A “negative” profile cutter which is the mirror image of the first cutter, above.This cutter will cut the decorative edge visible on the door front and it will cut the groove needed for the door panel A “positive” profile cutter for the inside of all rails and stiles.What is a Shaper What are the parts of a door cutter setĪ basic door cutter set consists of three cutters. Not sure what a shaper is? Check out this description in Wikipedia. Your choice of cutters will depend on whether you own a router table or a shaper. To make these raised frame and panels you will need a door-making cutter set. The photo below isn’t a raised panel but it give you a sense of the door parts. During assembly, the rails and stile are glued together, but no glue is applied to the panel since it needs to be able to expand and contract freely with seasonal fluctuations in temperature and humidity. The panel floats in a groove cut into the inside of the rails and stiles.

The rails and stiles form the frame around the panel. One is required.Īdditional components can be added if the door is large, or for esthetic reasons. Panels – This is the field (center) of the door.Rails – These are the horizontal components.Stiles – These are the vertical components.Check out all of their classes at Florida School of Woodwork The Parts of a Cabinet DoorĪll raised panel doors are comprised of three components: The Florida School of Woodwork offers classes in several different aspects of cabinet making and door making. This post will walk you though the steps to build a raised frame and panel door and if you’re interested you can sign up to the get excel spreadsheet that will help you do some of the basic calculations. There are lots of different choices and lots of different hardware considerations, but one door style that makers come back to time and time again is the frame and panel door and particularly the raised panel door.įrame and panel doors solve the problem of wood movement that can happen with wide wood doors and the raised panel gives it an elegant finished look.

Stiles and rails panel detail how to#

How to Make A Raised Frame and Panel DoorĬabinets usually need a door or two and deciding on the style of the door can be make or break the appearance of the piece.

0 kommentar(er)

0 kommentar(er)